|

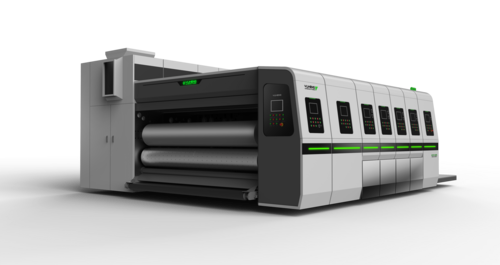

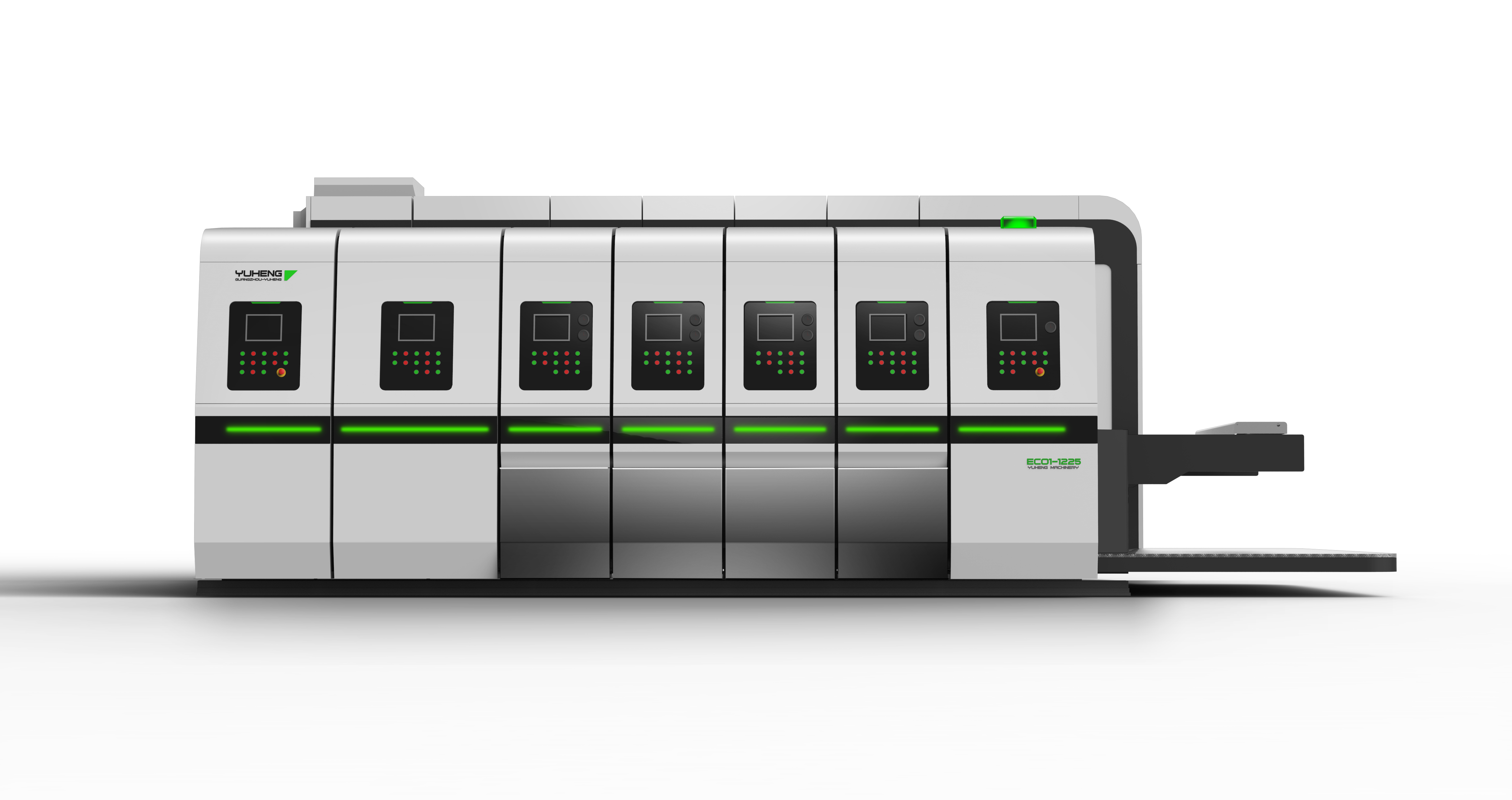

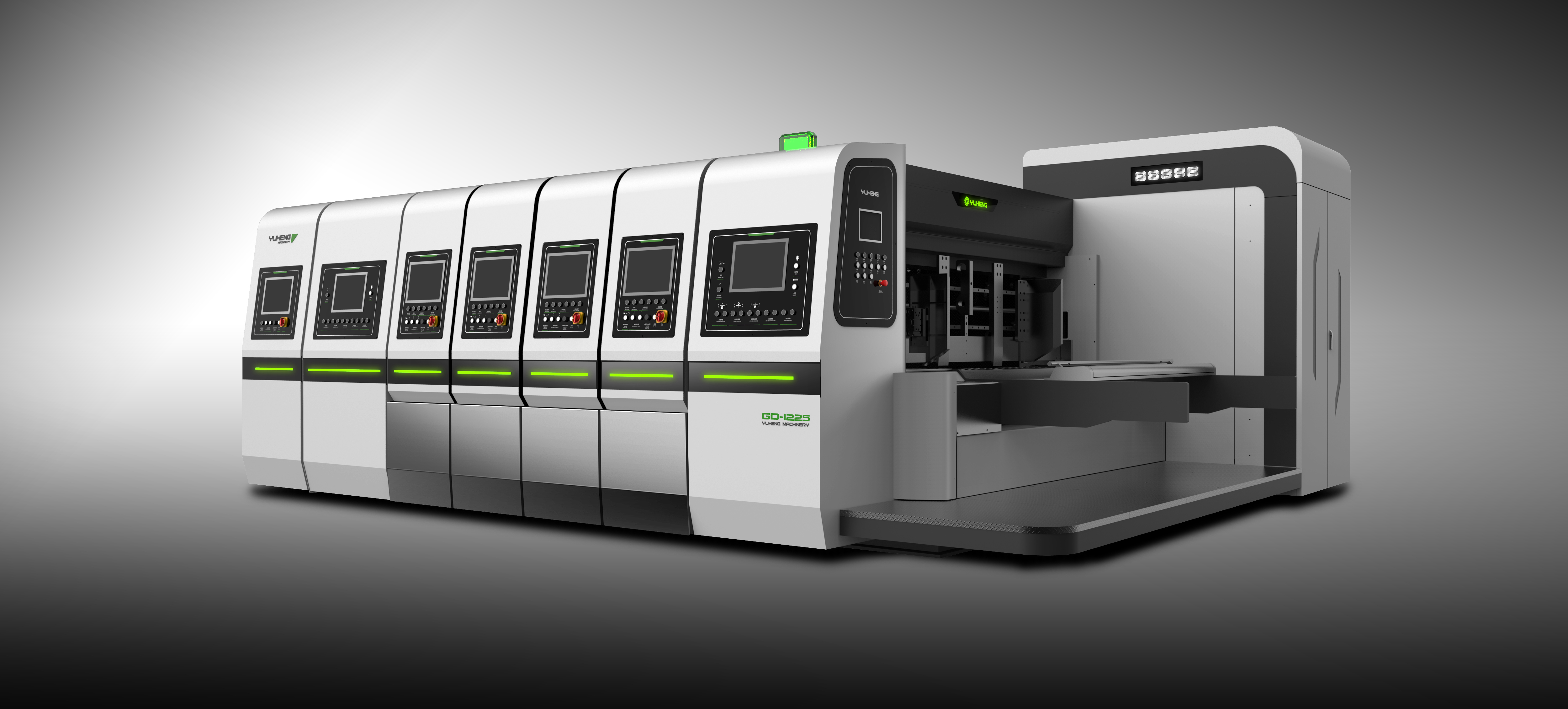

Corrugated Box Printing Slotting Die cutting Gluing production line

Product Details:

- Product Type Industrial Digital box Printer

- Material ink

- Capacity 350 pcs/min Pcs/min

- Computerized Yes

- Automatic Grade Automatic

- Control System Human Machine Interface

- Processing Type Automatically

- Click to View more

Corrugated Box Printing Slotting Die cutting Gluing production line Price And Quantity

- 1 Unit

- 9999 USD ($)/Unit

Corrugated Box Printing Slotting Die cutting Gluing production line Product Specifications

- ink

- Automatic

- Yes

- Human Machine Interface

- 350 pcs/min Pcs/min

- Automatically

- 220 Volt (v)

- Industrial Digital box Printer

Corrugated Box Printing Slotting Die cutting Gluing production line Trade Information

- 10 Unit Per Year

- 120 Days

Product Description

Feeding unit:

Single,continuous,skip-feed mode setting available

Adopt transdueer to control the main motorequipped with start protection function

Lead-edge feeding system made by Qualitymore stable and accurate feeding

Adopt transdueer to control the main fan,autornatic adjustment according to the

running speed of the machine

Dust removal equipment,Auti-static double brush and suction,clear dust and scrap

on paperimprove the cardboard printng quality

Feeding rubber roll clearance,the left and ringt side-plates place,back bafle

height compute seting an automatic adjustment

Production amount and waste cardboard amount can be set to ensure precise

production amount.

Electric adjustment the width for the paper

Left side pan atach alignment structure

Printing unit(Vacuum transsfer system):

Computer colour flexo printer Slotter cutter & Auto stacker design and more

Ceramics anilox rol delay function,can automatically elevate and fall in sequence

Adopt PLC to control independently each unit,PMs(Production Macagement s

according to the feed system

The whole machine adopt Germany slEMENs system.

Printing phase,computer seting.and Automatic adjustment Menmory funeon,

restore to the original position

Equipped touch screen in each unit,direct parameter seting and clear data dis

Computer set and automatiealy adjust printing plate,with ranget/-10mm

Main gears and shaft heads adopt keyless linkage ring

Push rolls clearance,the clearance between anilox and printing roll,computer

Adopt oil pump automatic spraying system to lubricate gear

seting and automatic adjustment

Al units is equipped emergency stop control switch,to ensure the operator safe

The oil automatic balance device,al units same level oil maintains

Each unit movement continued bellwarning,ensure the security of operator.

Sloting phase and case height computer seting and automatic adjustment

memory function,restore to the original slotting position afer midway adjustment

Fxed sloting phase,equipped automatic braking system

Sloting knife holder,pinch rollpush foll move transverse adjustment, computer

seting,automatic adjustment

sloting kniie shaft clearance pinch rol and push rol, computer seting,automatie

adjustment

sloting kniie shaft clearance,pinch rol and push roll computer seting, automatie

adjustment

Die cutting unit:

Adopt one-way structure for velocity compensation to ensure more accurate die

cuting

Die cuting roll clearanee,feed roll clearance computer set automatic adjustment

Die cuting phase computer seting,automatic adjustment with memory function,

restore to the original sloting position after midway adjustment

Die cuting roll transverse movement computer seting.and automatic adjustment

Fixed die cuting phase with a braking system.

Rubber mat grinding system,flexibly grinding rubber mat

Die cuting rol hydraulic transverse movement device around.uniform atition

can improve rubber mat service life.

Guide puleys in feeding unit adopts auto lovkeasierto adust axial directon

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Corrugated Box Machine' category

|

Hmw Tech Co., Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |